The expertise makes the difference

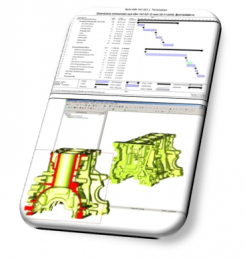

In supporting product development of our customers, Eisenwerk Brühl has highly qualified and motivated employees. We provide our expertise from one location, from CAD modelling to the complete layout of the foundry tools. That makes us a preferred contact for the customers development of high tech castings for the engine. To support our customers we have a variety of modern software tools, such as different CAD software up to casting simulation tools.